Achieving a successful pearl finish in collision repair requires meticulous pre-treatment and surface preparation. This includes thorough cleaning and drying, followed by precise sanding and priming to ensure uniform paint adhesion. Skilled technicians use specialized agents and consistent application pressure to maintain consistency. Careful removal of the old matte finish using hand sanding or equipment like heat guns prevents damage and ensures a flawless base for the new pearl finish.

In the realm of automotive aesthetics, pearl finish collision repair is a delicate art. While aiming to restore vehicles to their former glory, technicians face unique challenges that demand precision and expertise. From pre-treatment and surface preparation to application, drying, and post-repair inspection, every step requires meticulous attention. This article explores common hurdles in the pearl finish collision repair process, delving into key areas such as surface uniformity, coating consistency, quality assurance, and more, offering insights for professionals striving for flawless matte finish collision repairs.

- Pre-Treatment and Surface Preparation

- – Uniformity of Surface Cleaning and Priming

- – Challenges in Removing Old Finish Without Damage

Pre-Treatment and Surface Preparation

The success of any pearl finish collision repair hinges on meticulous pre-treatment and surface preparation. This initial step involves thoroughly cleaning the damaged area to remove all contaminants, such as dirt, grease, and wax. This is crucial as any remaining debris can affect the adhesion of the final coat, leading to an uneven or flaky finish. After washing and decontaminating, the surface must be properly dried to prevent water spots from marring the matte finish.

Surface preparation also includes sanding and priming. Auto body work experts use specialized sandpaper to smooth out imperfections and create a roughened surface that enhances paint adhesion. This is followed by applying a primer, which acts as a bridge between the damaged panel and the final pearl finish coat. Choosing the right primer for the specific type of auto collision repair is essential to ensure compatibility and optimal bonding with the topcoat.

– Uniformity of Surface Cleaning and Priming

Achieving uniformity in surface cleaning and priming is a significant challenge in pearl finish collision repair. Unlike matte finish collision repair, where inconsistencies might be less noticeable, the reflective nature of pearl finishes demands precision. Even slight variations in cleaning or priming can result in visible disparities that compromise the final aesthetic. Technicians must meticulously follow established protocols to ensure every square inch of the damaged area is treated evenly. This includes using specialized cleaning agents and primers designed for pearl coatings, as well as applying them with consistent pressure and depth.

Priming plays a critical role in bridging the gap between the damaged surface and the pearl finish. Incarcerated air bubbles or uneven primer application can create imperfections that show through the glossy topcoat. Skilled technicians understand the importance of thorough drying and careful inspection to identify and rectify any issues before proceeding to the next stage of repair. This meticulous attention to detail is what sets apart exceptional car collision repair services, ensuring the restored vehicle not only looks good but also maintains its high-end finish.

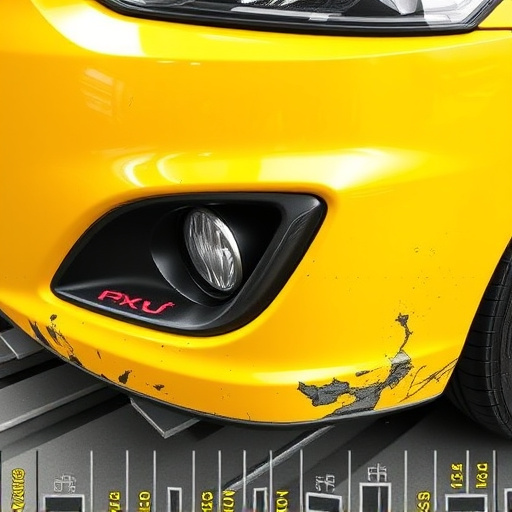

– Challenges in Removing Old Finish Without Damage

Removing old finish during pearl finish collision repair can be a delicate process, presenting several challenges. One of the primary hurdles is ensuring that the existing matte finish is thoroughly stripped without damaging the underlying surface or compromising the final aesthetic. The use of aggressive chemical strippers or mechanical methods can leave scratches or remove too much material, affecting the overall quality of the car body restoration.

Proper techniques and tools are essential to navigate this challenge. This often involves hand sanding with progressively finer grits to gently buff away the old finish while maintaining the shape and integrity of the panel. Additionally, professional technicians may employ specialized equipment, such as heat guns or vapor degreasers, to minimize the risk of damage during the de-finishing process. These methods are crucial for achieving a flawless base before applying the new pearl finish, ensuring a top-quality auto glass repair outcome.

In navigating the intricate process of pearl finish collision repair, understanding and overcoming common challenges is paramount. From ensuring uniform surface preparation to carefully removing old finishes without damage, every step demands precision and expertise. By mastering these techniques, professionals can deliver exceptional results, transforming damaged surfaces into stunning, like-new matte finishes, catering to the highest standards in the industry.